Design for Manufacturing and Assembly: Optimizing Product Development

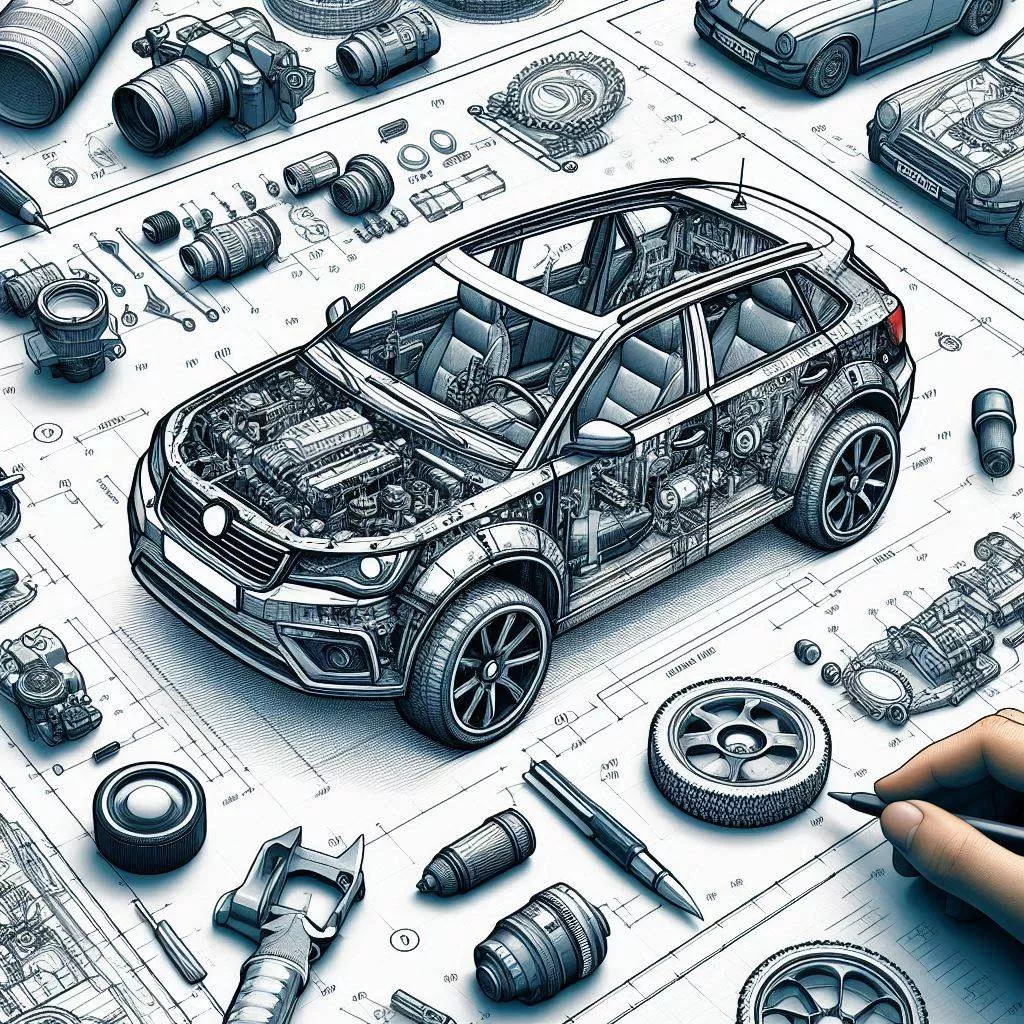

Product development requires an integrated bringing together design, engineering, and manufacturing teams. By adopting Design for Manufacturing and Assembly (DFMA) companies can optimize processes, ensuring efficiency from the early stages of product conception. This methodology incorporates manufacturing and assembly factors from the outset of product conception. By aligning design with production, it can significantly impact product cost, quality, and time to market.

DFM, a subset of DFMA, focuses on manufacturing efficiency choosing the right materials, refining production methods, and minimizing costs. DFA prioritizes assembly optimization, focusing on minimizing assembly duration, defects, and labor expenditures. When applied together, DFM and DFA create a powerful synergy that drives product success.

In today’s competitive market, where speed and cost-effectiveness are paramount, DFMA has become an indispensable tool for businesses seeking to gain a competitive edge.