How FEA is Revolutionizing Material Science

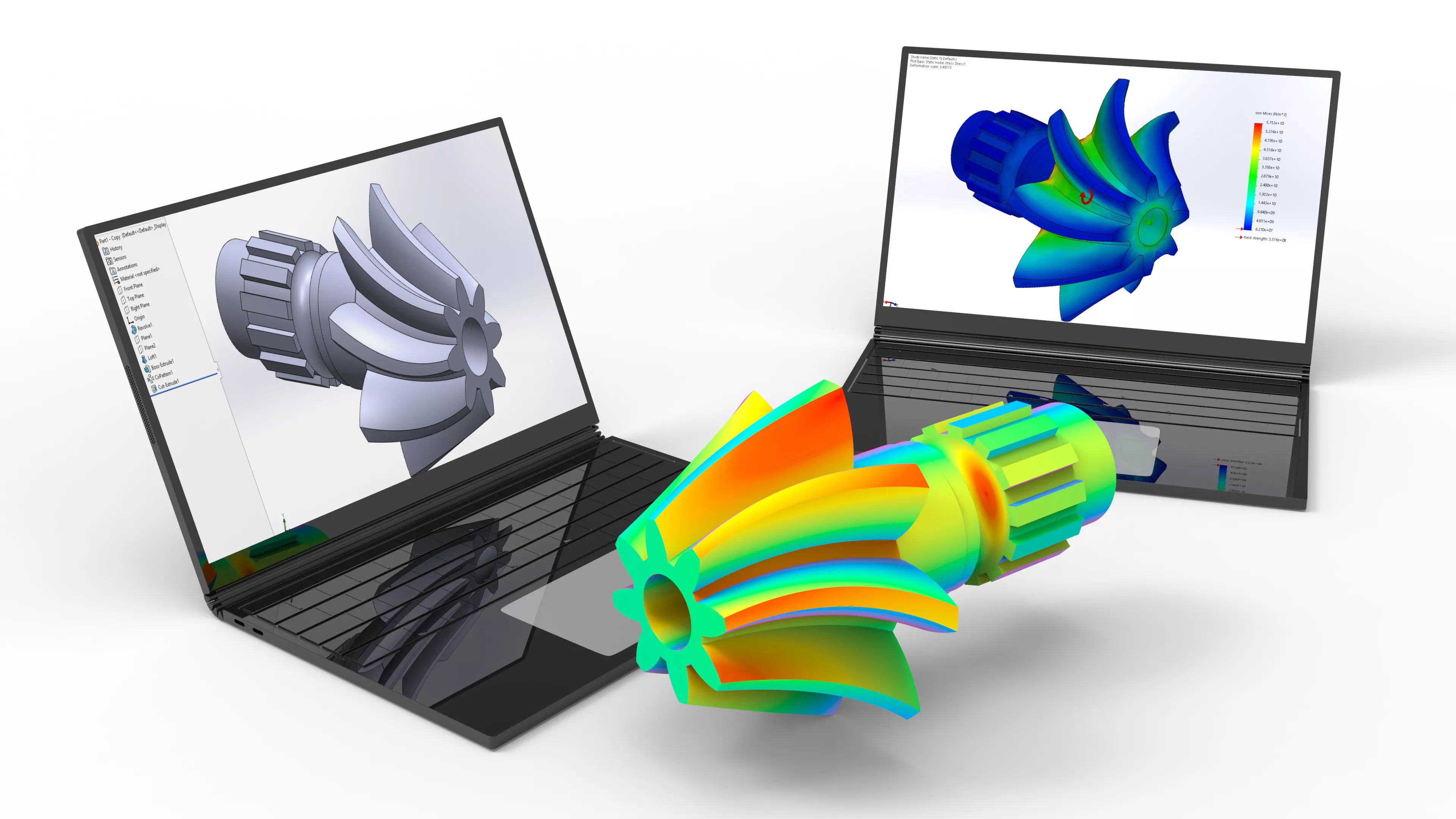

Finite Element Analysis (FEA) is a numerical technique that breaks down large, complicated engineering issues into smaller, easier-to-manage components. Using mathematical models, the computer-based simulation technique predicts the behavior of materials under different conditions. Richard Courant first introduced the Finite Element Approach, or FEA, in the 1940s. Finite element analysis, or FEA, has long been used by material scientists to study the behavior of materials under a variety of conditions. It allows us to assess and predict material performance without requiring costly and time-consuming physical testing procedures and environments.

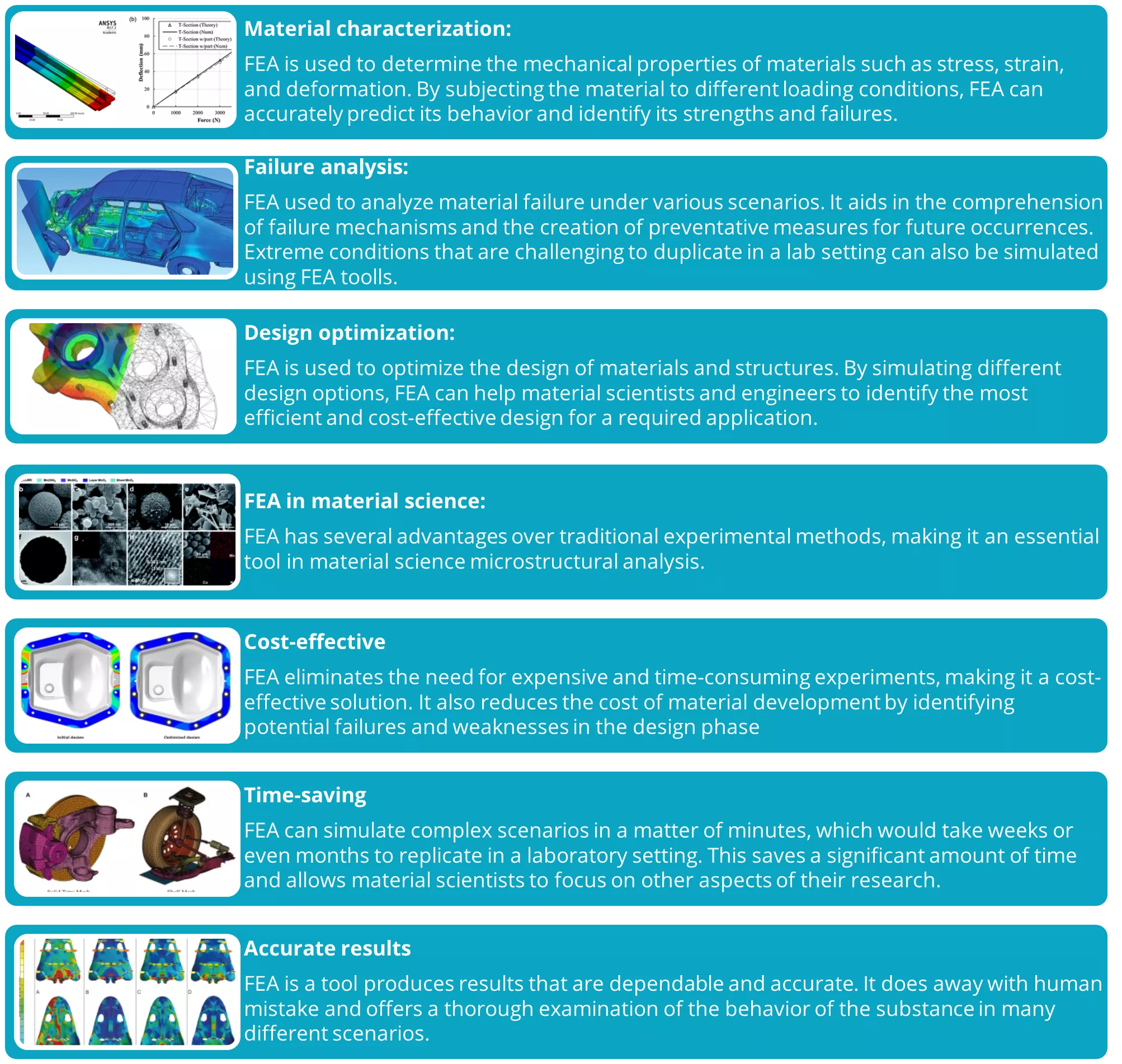

FEA is used in material science in the following ways:

FEA goes beyond basic simulations in Material Science:

Finite Element Analysis (FEA) is transforming material science by providing a powerful computing tool for academics and engineers. Optimization solutions can be achieved by modifying, adapting, and changing simulation models to meet different known or expected operational situations. The designers may rest easy knowing that the actual things will perform properly and safely.

- Multiscale Modeling: Multiscale, complex problems can be handled via FEA. Picture yourself enlarging a macroscopic object to reveal its constituent atoms. A more complete overview of material behavior which can be obtained by connecting and incorporating various models at each scale with the help of finite element analysis (FEA).

- Non-linear Material Behavior: Most of the materials exhibit non-linear behavior under stress or strain. To simulate complicated material responses more realistically, FEA can take these non-linearities into consideration. This holds particular significance for materials undergoing significant deformations, such as composites.

- Integration with Other Techniques: Machine learning and other computational technologies can be successfully combined with FEA. This enables scientists and engineers to spot trends in the behavior of materials and even apply machine learning to forecast the qualities of materials from sparse data or predetermined specifications.

- Advanced FEA Techniques: Advances in FEA methods tailored to material science are continuously being made and implemented. Methods for simulating the behavior of composite materials with various components, failures, and fracture mechanics are among them.

How FEA's influence on various aspects of material science:

- Microstructure & Mechanical Properties: FEA may simulate a material's microstructure, such as grain size porosity and phase distribution. This enables researchers to comprehend how these characteristics affect mechanical attributes such as strength, ductility, and fatigue resistance.

- Predicting Anisotropy: Materials can exhibit varying properties in different directions (anisotropy). FEA may account for this by including the material's crystalline structure, resulting in more accurate models of real-world behavior and functionality.

- Material Design & Optimization: Topology Optimization: FEA is utilized in topology optimization, which is when software removes redundant material from a design while keeping it functional. This leads to lighter and stronger components.

- Multi-material Design: FEA is used in topology optimization, which is the process of removing unnecessary material from a design while maintaining functionality. This results in lighter, more durable components.

- Failure Analysis & Material Selection: Virtual Testing of Failure Modes: FEA is utilized in topology optimization, which is the act of reducing unneeded material from a design while keeping it functional. This leads to lighter, more durable components.

- Predicting Service Life: FEA can estimate a material's service life and assist engineers in selecting materials for long-term durability by simulating how it degrades under different operating circumstances (temperature, pressure, etc.).

- Emerging Applications: In additive manufacturing, FEA is used to simulate the 3D printing process and predict probable errors such as warping and residual stresses. This helps optimize printing parameters and ensures that the finished product meets performance standards.

- Biomaterials & Drug Delivery: In biomaterials research, FEA is used to understand how these materials interact with living tissues. It can also simulate drug delivery mechanisms from materials designed for targeted drug release.

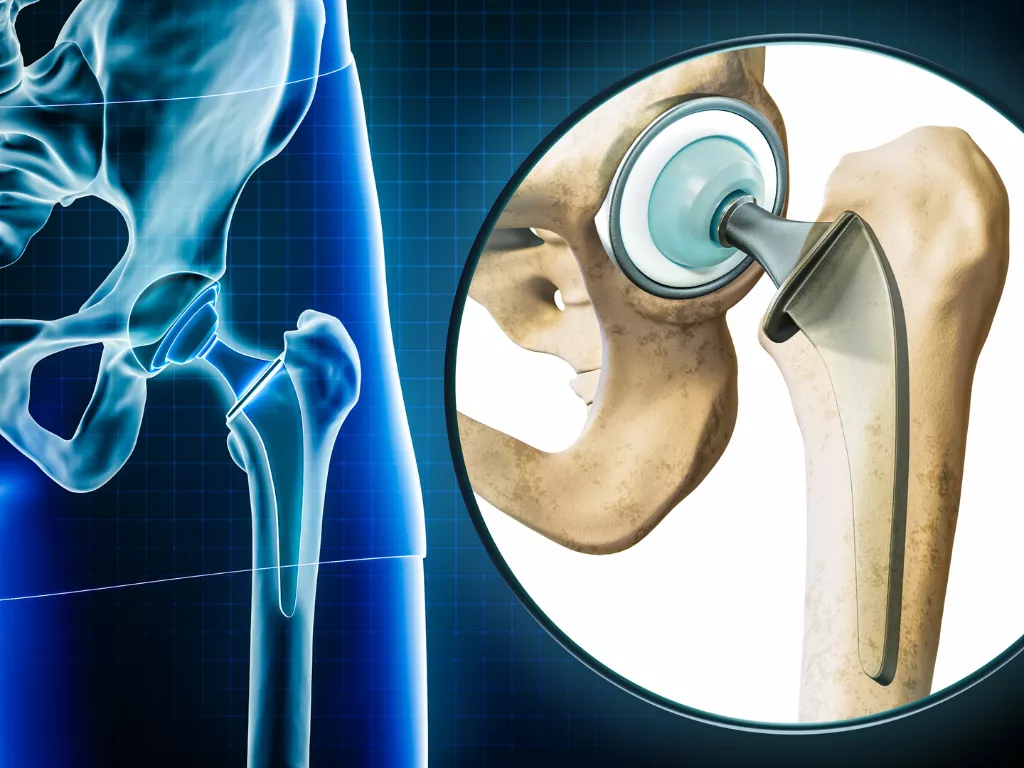

Case study: FEA revolutionizes hip replacement design with biocompatible materials

Surgery to replace the hip is frequently performed on patients with severe osteoarthritis of the hip. These implants have often been made of metal alloys such as cobalt chromium. Although these materials are quite strong and durable, there are worries about how long they will last and whether they would leak metal ions into the body. Furthermore, stress shielding - a condition in which the surrounding bone shrinks because of reduced load bearing - can result from the rigidity of metal.

Medical device engineers are leveraging FEA to develop new hip replacements that address these challenges. Here's how FEA plays a crucial role:

- Material Selection & Optimization: FEA allows researchers to virtually test different biocompatible materials like ceramics or composites. By simulating stress distribution and wear patterns, they can identify materials that minimize wear debris and reduce stress shielding on surrounding bone.

- Design Optimization with FEA: FEA helps optimize the implant's geometry. Engineers can analyze how different shapes and porous structures affect stress distribution and stability. This can lead to lighter, more bone-friendly designs that promote long-term implant fixation.

- Predicting Long-Term Performance: FEA simulations can predict the implant's behavior over time. By simulating wear and tear under various physiological conditions, engineers can assess the implant's longevity and identify potential failure points before physical prototypes are even created.

This case study demonstrates how FEA is revolutionizing the medical device industry by enabling the development of more biocompatible and durable hip replacements. FEA is a powerful tool that will continue to play a vital role in advancing material science for the benefit of patients around the globe.

How Decos Can Help Clients with FEA Support

At Decos, we collaborate closely with our clients to understand their unique challenges and needs, adopting a human-centered approach to problem-solving. We offer pre-defined workflows for common Finite Element Analysis (FEA) tasks, simplifying the setup process for clients with limited FEA experience. Our optimized algorithms automatically adjust design parameters to achieve desired performance goals.

Additionally, Decos enables clients to easily compare results from multiple simulations, helping them identify trends and make informed design decisions.

Throughout the development process, we prioritize user feedback and iterative improvements, ensuring that our products and services meet the highest standards of success and client satisfaction.

This Blog is written by Dr. Mohammed Basheer, Senior Mechanical Engineer at Decos with 9+ years of experience in product lifecycle management. He has proven expertise in product design, development, and manufacturing, with a strong focus on Additive Manufacturing, materials engineering, process optimization and delivering innovative solutions from concept to commercialization.

Decos is a cutting-edge technology services partner ready to meet your software needs in the medical domain. If you have a question on one of our projects or would like advice on your a POC, just contact Devesh Agarwal. We’d love to get in touch with you!

Discover more

Transforming Instructions for Use (IFU) with AI: Enhancing Technical Documentation

Reducing Latency in Real-Time Medical Monitoring to enhance speed, accuracy and patient safety.