From prototypes to market-ready products:

engineering excellence tailored to your needs

At Decos, we provide a comprehensive range of mechanical engineering services designed to meet the highest industry standards and customer specifications. Our expertise spans across various domains, ensuring innovative and efficient solutions for your needs.

New Product Development

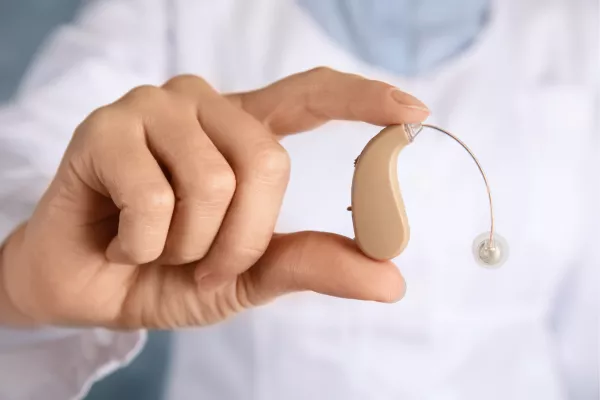

Transform raw ideas into tangible product concepts, creating sleek, functional, and user-centric designs. We lead the development of new products from concept to prototype and subsequently to the market, applying mechanical engineering principles to create innovative and practical solutions. Our expertise includes:

- Creating engineering prototypes and resolving assembly issues,

- Support in conducting pilot lot production for a seamless transition to manufacturing.

- Experienced in various fields including Medical Systems, Healthcare Devices, Biomedical Equipment, consumer electronics, etc.

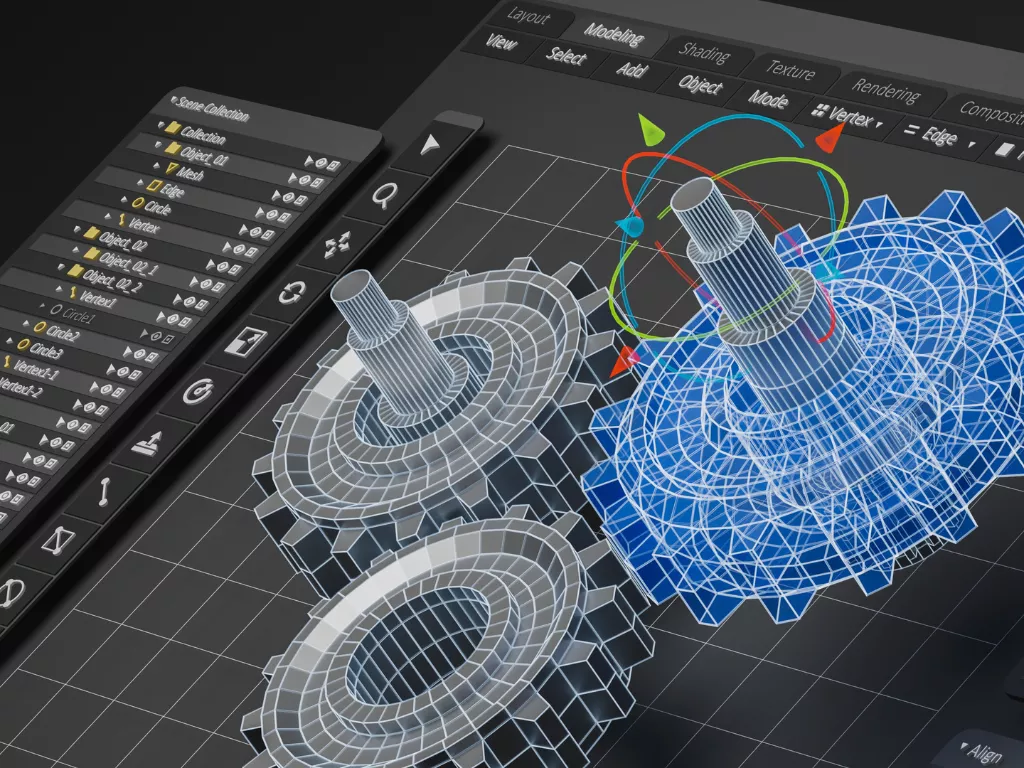

CAD Modelling Services

Achieve precision and efficiency with our advanced CAD modeling services.

We create 3D Models of components and assemblies using CAD software with expertise in 3D modelling, sheet metal, plastics product design and drafting. We also do Interface and Stack up Analysis for a perfect assembly fit and help our clients to create high-definition renderings images with aesthetics validation.

Design, Development and Manufacturing of Plastic Products

We offer a comprehensive range of services in the design, development, and manufacturing of plastic products with hands-on experience in Mould Design, Mold Flow Analysis, process expertise in Injection, Extrusion, Blow Moulding and Stamping. Our goal is to provide innovative and efficient solutions that meet the highest standards of quality, performance, and sustainability.

Material Testing and Characterizations

Ensure the quality and success of a finished product through informed selection of materials.

We provide comprehensive material testing and characterization services to ensure the quality, performance, and reliability of products. Our detailed reports and data analysis help you make informed decisions.

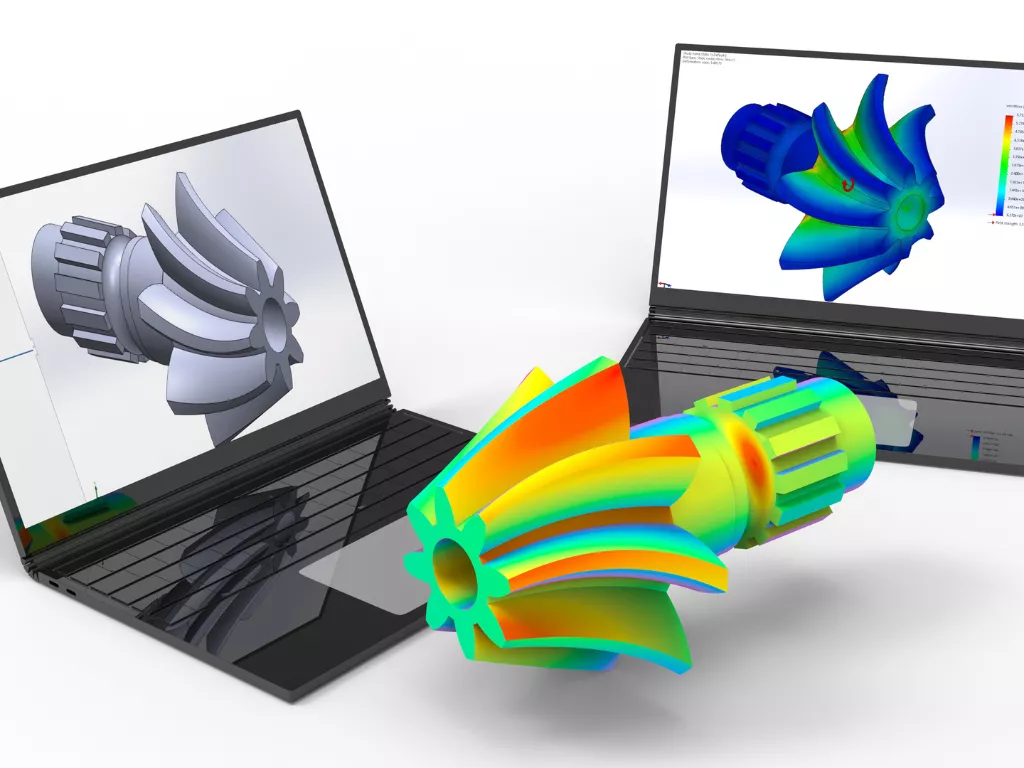

Simulation Services

Our mechanical simulation services use advanced computational tools to predict and analyse the behaviour of various mechanical systems. These services are essential for verifying designs, optimizing performance, and ensuring safety and compliance.

- Finite Element Analysis (FEA): We use FEA to simulate and analyse the structural integrity and performance of components and assemblies, predicting how products react to real-world forces, vibration, heat, and other physical effects.

- Structural Optimization: We can help in improving the design of a product to meet specific performance criteria while minimizing weight and material usage, enhancing efficiency and effectiveness.

- Thermal Analysis: We evaluate the thermal performance of products to ensure they can withstand and operate efficiently under various thermal conditions.

- Fatigue and Durability Analysis: We assess the durability and reliability of products under cyclic loading conditions, identifying potential failure points and suggesting improvements to extend operational life.

- Vibration Analysis: We study the vibrational characteristics of structures and components to ensure they can withstand vibrational forces without failure or performance degradation.

- Drop Test: We conduct drop tests to evaluate the ability of products or packaging to withstand impacts, simulating real-world conditions during shipping, handling, or everyday use.

PLM Services

Our Product Lifecycle Management (PLM) services help organizations streamline their product development processes, improve collaboration, and ensure compliance with industry standards.

- Bill of Materials (BOM): We prepare detailed BOMs and coordinate with vendor development teams for new component development.

- Engineering Change Management: We implement systems to manage and track changes throughout the product lifecycle by means of ECO, MCO and DCO Workflow, ensuring all modifications are documented, approved, and communicated effectively.

- Cross-Functional Coordination: We engage with production, assembly, quality, and vendor development teams to ensure a seamless development process.

- Engineering Library Management: Components Library creation and management, Preferred part identification and criterion definition to maintain data consistency and improving accessibility across the organization.

- Data Management: We offer services to facilitate real-time collaboration among design, engineering, manufacturing, and supply chain teams by moderating and managing data in Engineering Data Management, Product Data Management, and Enterprise Resource Planning tools.

Product Sustaining Engineering Services

We help clients identify and address the underlying causes of product failures, defects, or performance issues. Here are some key services offered by Decos:

- Product Performance Improvement

- Feature Enhancements

- DfX and Value Engineering

- End-of-Life and Obsolescence Management

- Documentation and Design Remediation

- Root Cause Analysis (RCA)

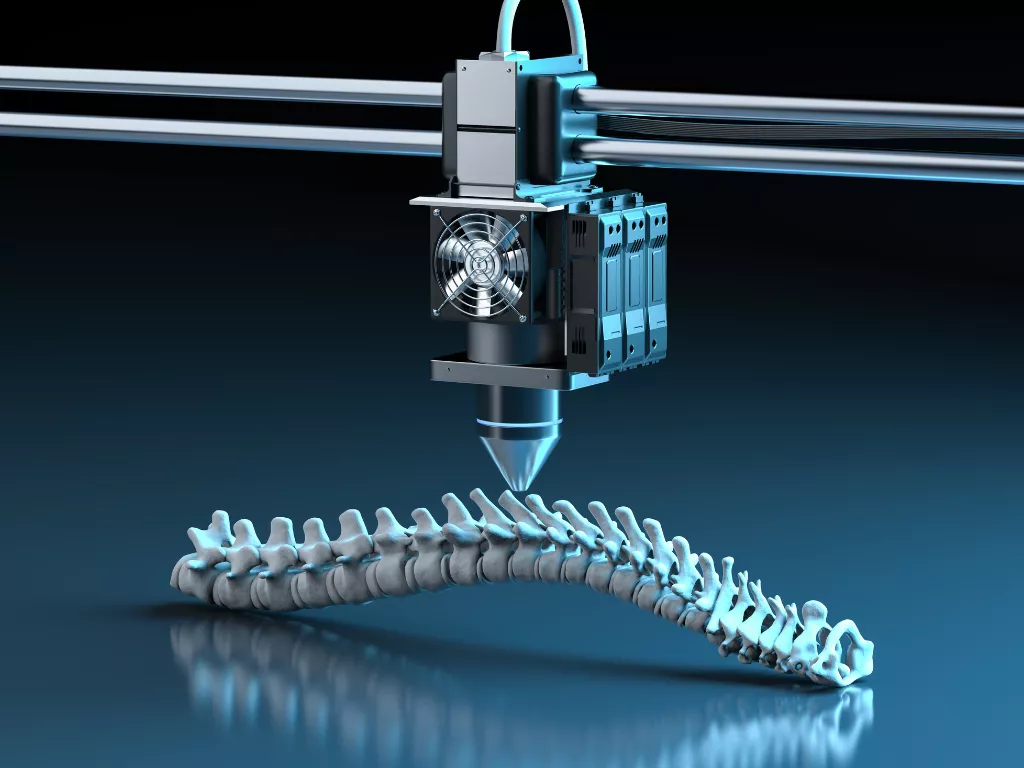

Rapid Prototyping and Additive Manufacturing Technology

We specialize in rapid prototyping and additive manufacturing technologies, including concept modelling, functional prototyping, design validation, and pre-production tooling, to accelerate product development and reduce time-to-market.

Re-engineering Services

Our engineering services team will analyze and replicate existing products. We can help in acquiring high-precision 3D scanning to capture detailed geometric information, create accurate 3D CAD models from scan data or physical objects, and conduct detailed analysis of product components, materials, and manufacturing processes. We identify areas for improvement and redesign for enhanced performance.

TECHNOLOGIES WE EXCEL IN BUT don't limit ourselves to

INDUSTRIES WE SERVE

LIFE SCIENCE | AUTOMOTIVE | Medical device OEMs | MANUFACTURING

WHY CHOOSE US

A Partner That Takes Ownership Beyond Tasks

Expand your potential with our end-to-end mechanical engineering services.

At Decos, we specialize in running entire projects with a focus on delivering exceptional results. We take full ownership, managing projects from initial design through implementation to ensure exceptional outcomes. Partner with us for comprehensive services tailored to meet the demands of your larger initiatives.

35+ Years experience

260+ Curious people

200+ Successful projects

200+ Happy Customers

Global presence

EXPERTISE IN TECH

Our team of engineers excel in crafting software solutions, boasting a proven track record of delivering complex projects.

FLEXIBLE PARTNER

We adapt to changing project requirements, maintain steady progress, and prioritize client satisfaction through active feedback and problem-solving.

USER-CENTRIC

We prioritize user experience, ensuring our solutions simplify processes and effectively meet user needs.

CULTURAL ALIGNMENT

We facilitate seamless collaboration across cultures, time zones, and workflows, ensuring clear communication and effective partnership.

How we work

Discovery

We engage with you to comprehensively identify your challenges, goals, target audience and expectations.

Ideation

We will brainstorm and come up with a solution and implementation strategy that best fits your challenge.

Implementation

We put the ideas into action and develop an MVP and MRP, then we incorporate all the feedback.

Delivery & Support

We deliver the product and stay involved for support, required improvements and any further developments.

OUR projects / WORK

Natus

Optimizing product development processes by providing services focused on Design for Manufacture and Assembly (DFMA).

Natus

Applying simulation and Computational Fluid Dynamics (CFD) for better medical device designs.

LET'S CONNECT

Curiosity is the driving force for positive change. A force without limits. With endless opportunities. When anything is possible, imagine where we can go next!

I am very curious about your challenge, so: let's connect!